Water Computing

High-end services in hydraulic analysis of ports, marine environment and dredging.

Driven by outstanding expertise in hydraulic engineering and numerical modelling.

WATER COMPUTING

Our goal is providing answers to your questions using the most appropriate modelling tool for each problem. We apply modelling software with open source code. In this way, we can implement features without limits, tailor-made for customer’s case. We are not bound to the limits of standard software versions.

Find out about our different modelling tools:

- Regional tidal flow models

- Nearshore wave climate models

- CFD/Fluid dynamics Marine & Coastal

- CFD/Fluid dynamics Inland hydraulics & ports

- North Sea metocean model

- Scheldt River model

- Dredge plume modelling

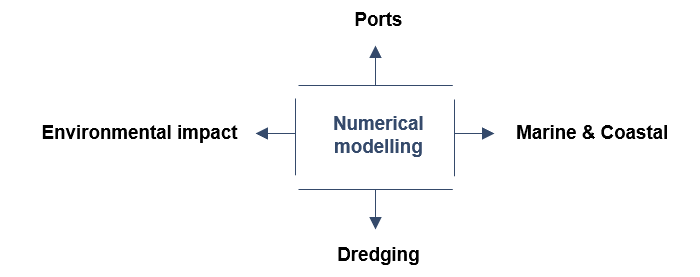

Numerical models are the core of this product’s expertise, applied to a range of markets:

Numerical models

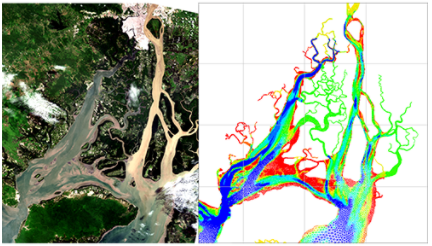

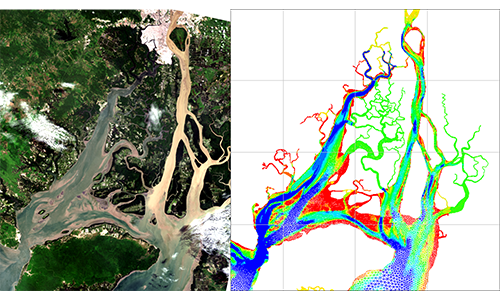

- 2D/3D hydrodynamic models: River, Coast, Estuary & Ocean

- 2D/3D Sediment models: Turbidity, sedimentation, erosion, settling ponds

- Plume dispersion models: dredge plumes, intake-outfall, thermal, brine, sewerage

- Computational Fluid Dynamics (CFD)

- Water Quality simulations Numerical models

Marine and coastal infrastructure

- Site selection

- Feasibility studies

- Metocean: monitoring & analysis

- Intakes-outfalls: design, impact, recirculation

- Workability / downtime

- Offshore installation (hydrodynamic loads, touchdown, DMA,…)

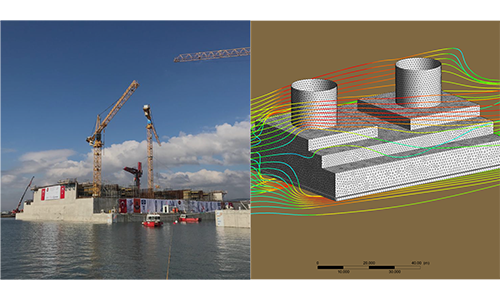

Ever-increasing computing power has rendered Computational Fluid Dynamics (CFD) as a valuable solution for optimisation, cost-effective hydraulic design or any fluid flow problem related to the offered services.

We learned that CFD is often still an unexplored field for optimisation and design, therefore one of our short-term goals reads: to deploy the benefits of CFD to a wide range of applications: hydraulic structures, immersed tunnel construction, offshore installation, wave loads and scour protection, to name a few.

Further, we provide water quality modelling for problems such as eutrophication and oxygen depletion.

The oceans’ plastic soup is drawing great attention. We apply numerical models for plastic transport in rivers, in order to determine optimal location to install river cleaning equipment. .